Your challenge

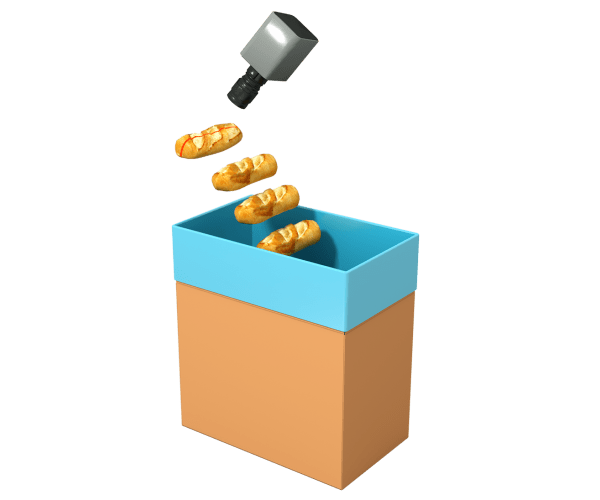

- Have a precise amount of products in your packaging unit

- Only pack those products within your customer specifications

- High speed production lines (10.000 loaves/hour, 12.000 baguettes/ hours, 80.000 rolls/hour)

- Pack with a diversity of packaging styles

- Control each kind of product

Our solution

- A unique vision counting machine, offering 25 years of successive development, which is the reference on the market (often imitated, never equalled)

- All packing lines can host quality control systems with the most accurate rejection systems on the market.

- The fastest production lines on the market are equipped with Pattyn solutions, presenting a large range of proven applications worldwide

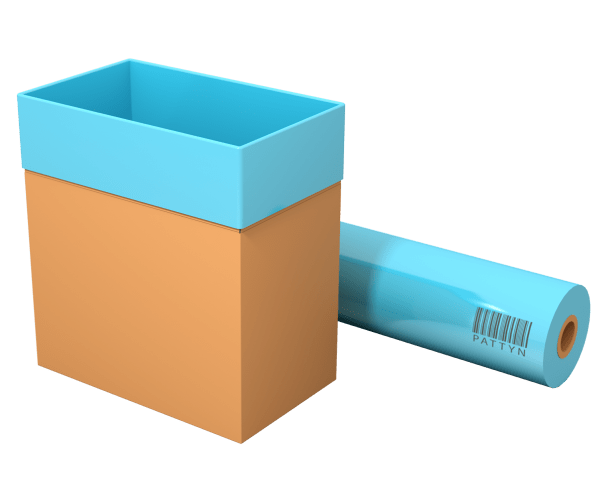

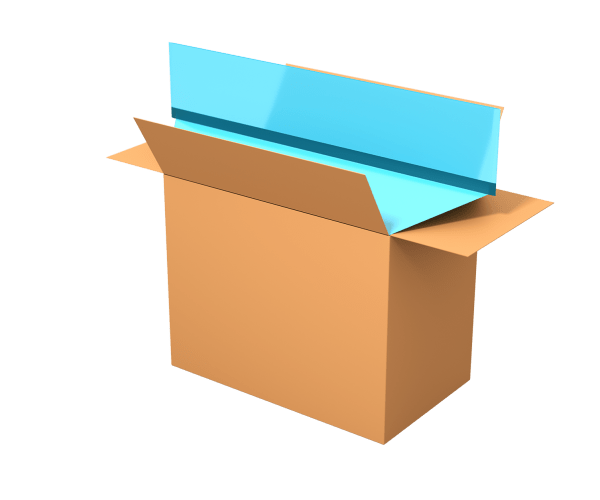

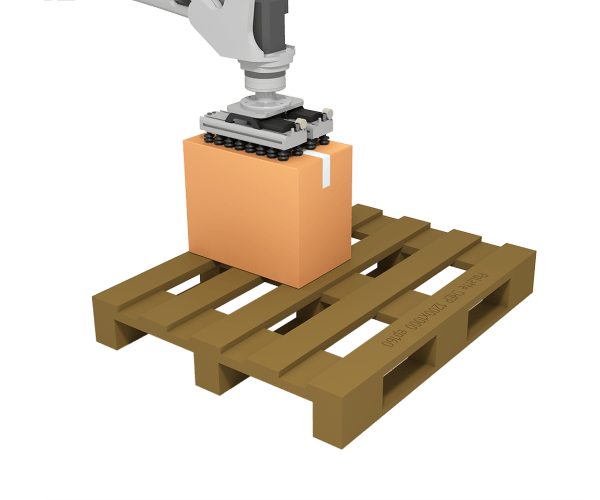

- Our vision counter and our quality control can count and control all types of products and can be combined with all packaging machines: case filling, VFFS …

Download brochure

Discover more about our bread packaging solutions in our brochure.

Packing patterns

For the standard filling line solution we have 6 types of packing patterns. With Pattyn you rely on specialists to help you solving your unique challenges.

Request meeting

Do you have a specific packaging challenge? Would you like to discuss it with us? With over 30 years of experience and know-how in industrial packaging of bread, we assist you in finding the optimal solution for you.

Contact

Would you like to receive additional information about our packaging lines or one of our specific machines?