Your challenge

-

Increase capacity

-

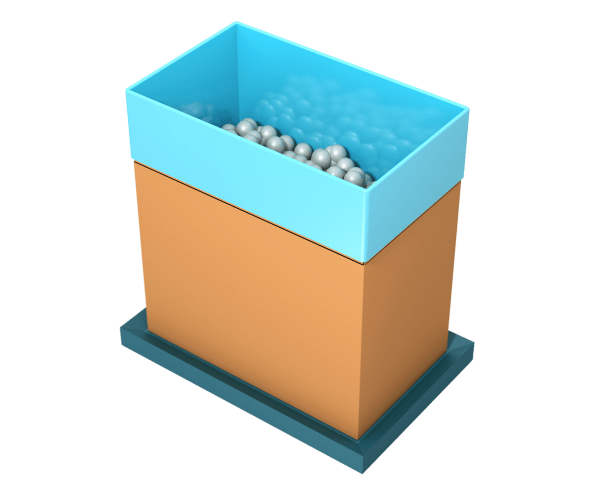

Minimize product giveaway & avoid splashing

-

Improve packaging quality

-

Packing into various containers

-

Packing different types of oils & fats

-

Run boxes and pails on one line

Our solution

-

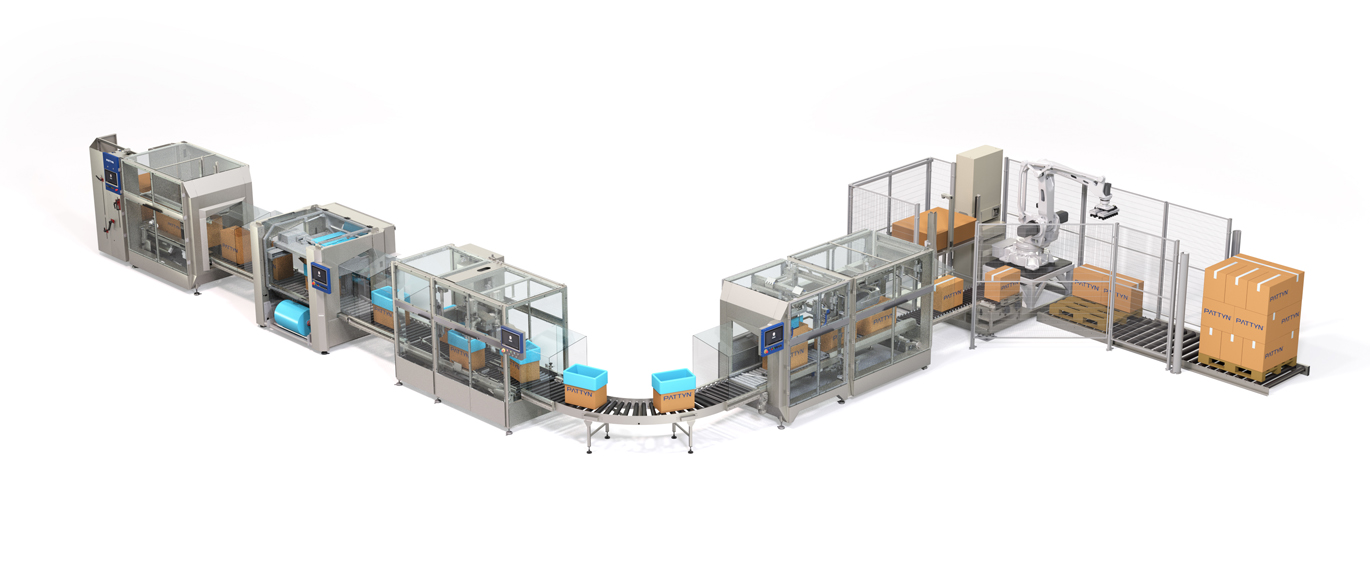

Fully automated high speed line

-

Most accurate semi-liquid filler on the market with anti-splash device

-

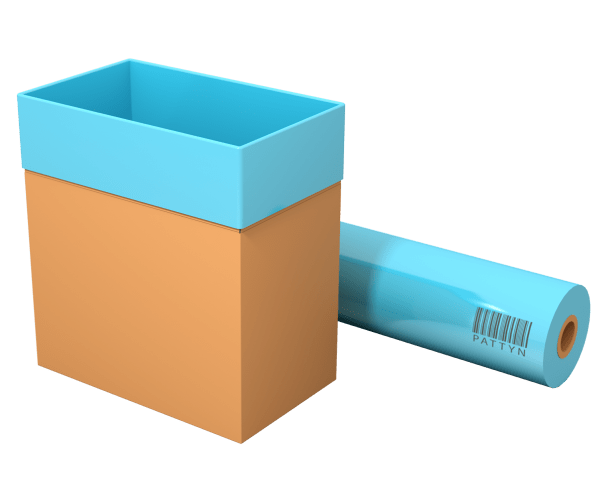

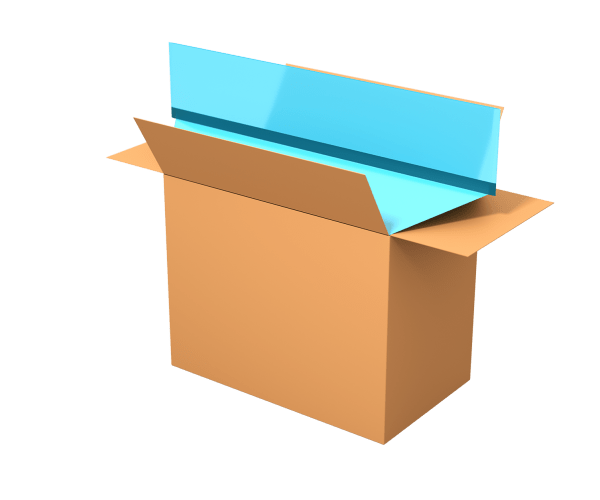

Sealed bag in a box, ready to be transported

-

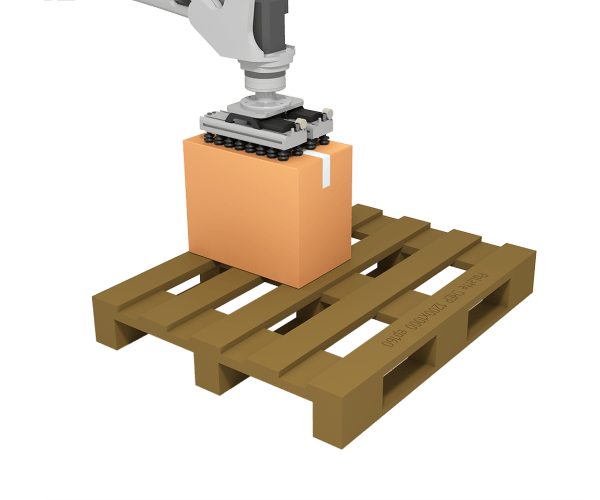

The bagmaker inserter and filler handle many different containers, such as boxes, tins, pails, drums, JIB’s, …

-

You profit from our experience with many types of oils & fats: palm oil, margarine, shortening, specialty fats, …

-

With the integration of a pail destacker and automatic lid placer you run both boxes and tins or pails on one line

Watch the virtual tour here

Discover in a couple of minutes our latest oils & fats packaging solutions and their unique features & benefits during a 360° Virtual Tour. Click here.

For an in-depth inside look and more detailed information, request your one-on-one session with one of our experts at info@pattyn.com.

Download Brochure

Discover more about our edible oils & fats packaging solutions in our brochure.

Containers

Depending on the specific needs, several types of containers can be used in an automated packaging line.

Request meeting

Do you have a specific packaging challenge? Would you like to discuss it with us? With over 70 years of experience and know-how in industrial packaging, we assist you in finding the optimal solution to safely pack your oils & fats.

Contact

Would you like to receive additional information about our packaging lines or one of our specific machines?