In this insightful read, we explore the complexities of fresh fruit production. Our analysis sheds light on the various challenges encountered by producers around the world. From the delicate handling of cherries and apples to the complicated processes in kiwis and pomegranates, each fruit has its own considerations in production and packaging.

The sweet and the sour of the industry

In the world of fresh fruit, producers must deal with many opportunities and challenges specific to the industry. One of the biggest challenges of this sector is the tight window for harvesting and packing. Furthermore, the short harvesting season impacts the ongoing search to find skilled operators. Many people are put off by the seasonal nature of the work and the labor-intensive manual tasks involved. Manually harvesting and packaging the fruit products is obviously very time-consuming and not the most efficient way of working.

In addition to harvesting, packing fresh fruit demands a unique approach as well. The fruits are mostly packed in low trays, which limits the packaging volume and slows down the process. Moreover, the productions runs 24/7 and, given the short harvest season, there is no time to waste for stops or maintenance.

Pattyn's automation for a fruitful success

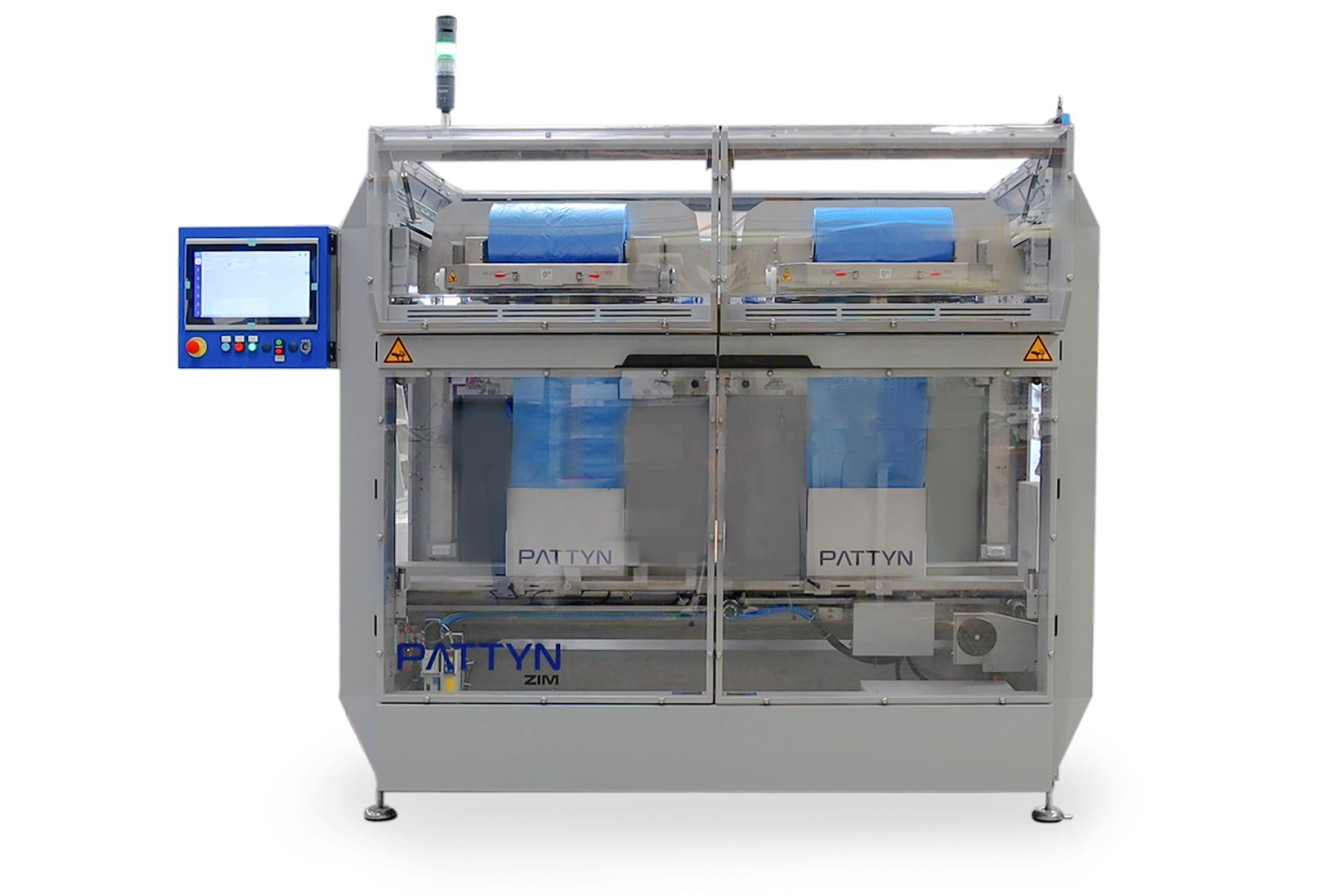

Fortunately, automated packaging solutions offer an answer to these pain points faced by the fresh fruit market. With Pattyn's automated packing machines, the manual packing process is a thing of the past, leading to less manpower and faster packing times. These machines have high packing capacity and advanced hygiene standards, addressing many of the industry's challenges. Not only does automation reduce manual labor, it also boosts operational efficiency and productivity, potentially adding to higher export volumes. Talk about a win-win situation!

Fruit producers don't have to worry about stops or maintenance because Pattyn's solutions are fast and the most reliable on the market. Furthermore, our automatic roll change enables non-stop production, making production faster and more efficient without interruptions. This allows fruit producers to breathe easy, as Pattyn's solutions ensure a smooth start to harvest and timely preparation. Plus, the automated systems contribute to reducing waste, resulting in less giveaway products.

In the fresh fruit industry, it's common to pack fruit products in low trays. No matter what type of box or tray is needed, Pattyn's turnkey solutions have the solution. The machines can handle different packaging types, allowing flexibility to run different sizes on a single line. This versatility ensures seamless operation tailored to the specific needs of the fruit product. And when it comes to folding or sealing trays, Pattyn's machines are recognized as the best on the market!

To wrap it up, Pattyn recognizes the time demands and challenges faced by fruit manufacturers during the short harvest season. Our automated solutions are designed to reduce this pressure and provide a comprehensive response to fruit producers worldwide. By implementing Pattyn's technology, the fresh fruit industry can kick-start their harvest with less hassle and squeeze out even more success.